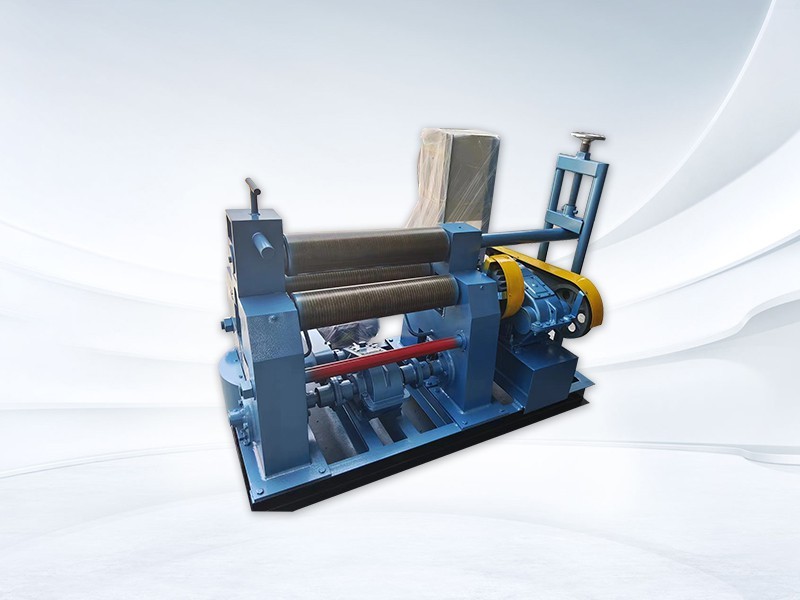

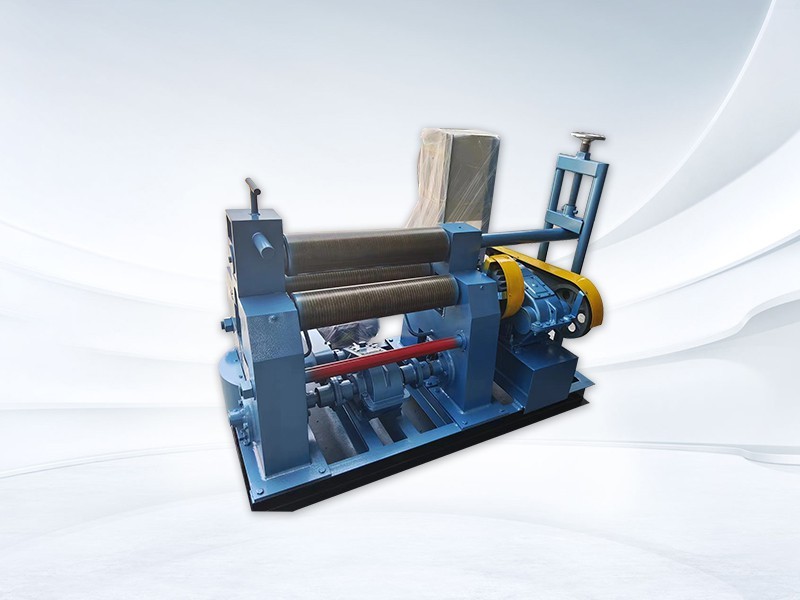

Lubricating the various transmission shaft necks and dynamic pressure sliding surfaces of the plate rolling machine is an effective measure to reduce the consumption of motion force and improve the service life of the plate rolling machine.For this,we need to choose the use of reasonable lubricating materials and establish necessary lubrication systems.The following will be explained in detail by China three roll plate bending machine manufacturer:

1.Lubrication method

According to the working conditions and different parts,the plate rolling machine has three methods:oil cup lubrication,manual refueling,and box lubrication.Each roller journal and transmission shaft journal are lubricated with oil cups;Regular manual lubrication is used for gears,turbines,lifting screws,movable bearings,and lifting adjustment mechanism screws;The lubrication of the gears and bearings inside the gearbox is mainly achieved by the oil splashing inside the gearbox.

2.Lubrication system and precautions

In daily work,oil should be injected into each lubrication point before each gear shift,and the lubricating oil in the gearbox should be checked to ensure it is at the specified level.The quality of the lubricant used in the plate rolling machine will directly affect the service life of the equipment.Daily maintenance of the equipment is crucial for extending the service life of the plate rolling machine and improving the efficiency of plate rolling.

Each lubrication point can only start the machine after sufficient lubrication.At the same time,if the machine is working continuously,the oil cup and manual lubrication are generally supplied once every two hours.The specific lubrication system should depend on the working system of the machine and its compliance with the operating conditions.The lubricating oil inside the gearbox is usually replaced every three months,not exceeding six months,and the entire lubrication system of the machine is cleaned once a year.

The above are the points to pay attention to when lubricating the plate rolling machine during use.Lubrication of the equipment is also a maintenance of the equipment,all for better operation.

Address:Room 1202, Detaitang Building, No. 118 Huaguang Road, Zhangdian District, Zibo, Shandong

Address:Room 1202, Detaitang Building, No. 118 Huaguang Road, Zhangdian District, Zibo, Shandong WhatsApp:+8615653328535

WhatsApp:+8615653328535 Wechat: +8615965331535

Wechat: +8615965331535  E-mail:zs@sdsmachinery.com

E-mail:zs@sdsmachinery.com